Espey WKA700

Espey WKA700

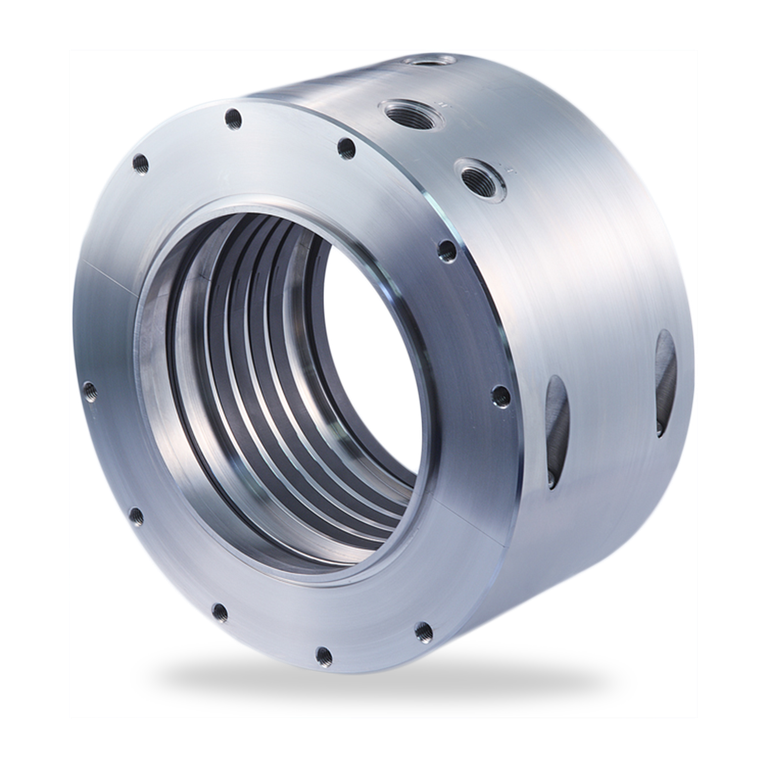

| Item | Description | Variable for width |

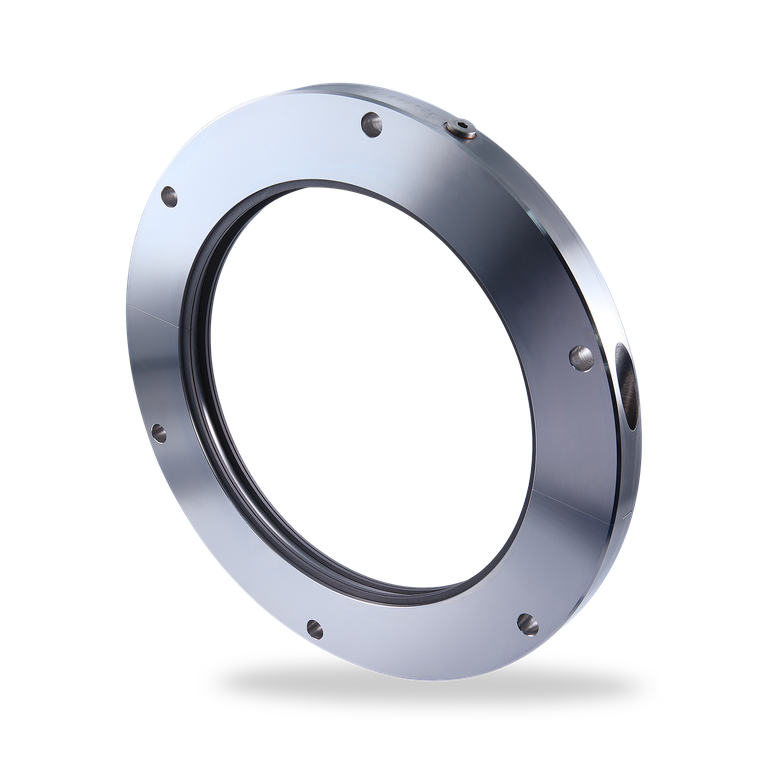

| 1.1 | Seal ring | |

| 1.3 | Pressure spring | |

| 2 | Chamber | A |

| 2.1 | Chamber with O-Ring | A |

| 3 | Barrier gas chamber | B |

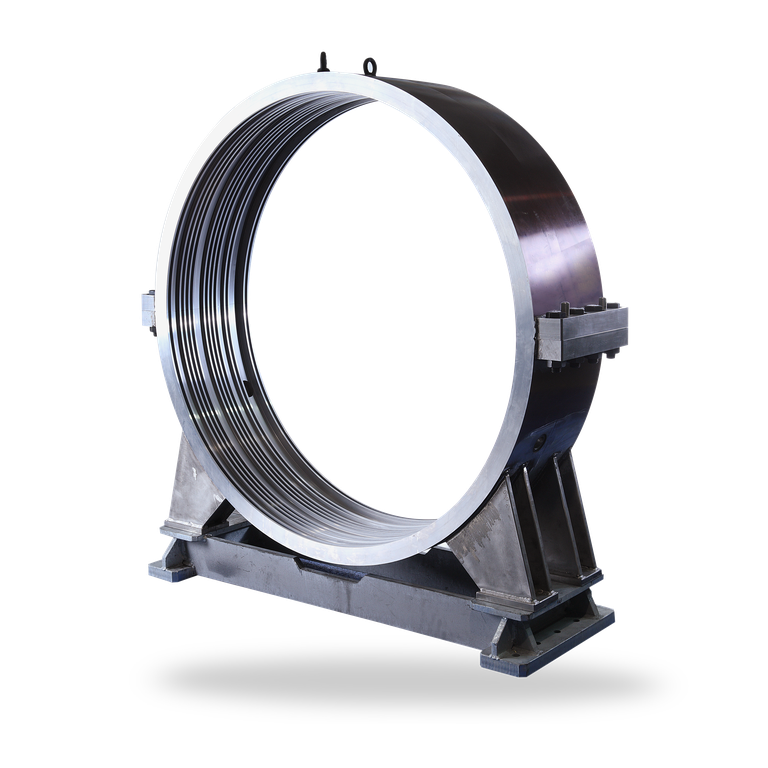

| 3.1 | Barrier gas chamber with O-Rings | B |

| 4 | Lantern chamber | C |

| 4.1 | Lantern chamber with O-Ring | C |

| 5.1 | Lantern breit | F |

| 6 | End ring | G |

| 7 | Flat seal | H |

| 8* | 8* Housing | |

| 9* | 9* Lid | |

| 10* | 10* O-Ring Housing |

* On request

Espey WKA700

Features

- Chamber seal (modular design - can be combined in any order), optinal with housing and lid for screw compressors with one-part and horizontally split housing

- Very small operation gap – low leakage

- Dry running

- Seal rings bear radial shaft movements

- Compensates axial shaft movements

- No sealing components mounted on the shaft and hence no additional shaft vibrations

- Seal rings running contact-free – sliding faces and machine consume no additional power

- One-piece seal ring with titanium bandage

- Both side balanced seal ring inside chamber for short-term backpressure operation

- Seal ring axially spring-loaded – no swinging up at pressure-less machine operation

Advantages

- High reliability

- Long-term operation time

- Maintainability

Materials

Seal ring: Carbon with titanium bandage

Chamber and housing parts: 1.4021, 1.4571, 1.4313

Hastelloy®, Titanium, Inconel®, others

Secondardy seal (elastomer): Fluorocarbon rubber

(Viton®), Nitrile-butadiene-rubber (Perbunan®),

Perfluorocarbon rubber (Kalrez®)

Secondary seal (gasket): Statotherm-HT/HD, KSiL C 4400

Chamber and housing parts: 1.4021, 1.4571, 1.4313

Hastelloy®, Titanium, Inconel®, others

Secondardy seal (elastomer): Fluorocarbon rubber

(Viton®), Nitrile-butadiene-rubber (Perbunan®),

Perfluorocarbon rubber (Kalrez®)

Secondary seal (gasket): Statotherm-HT/HD, KSiL C 4400

Standards and approvals

- FDA

Recommended applications

- Oil and gas industry

- Refining technology

- Chemical industry

- Petrochemical industry

- Pulp and paper industry

- Metal production and processing

- Power plant technology

- Gases

- Fumes and exhaust, solids containing, acid containing and toxic gases

- (Solids containing) steams/liquid mist

- Oil mist/penetrating oil

- Water

- Screw compressors

Similar products

Espey Magna500+ the large seal for diameters from 500 mm

- Split housing design

- Segmented and self-adjusting seal rings

- Virtually maintenance- and wearfree

- Dry-running

- Suitable for horizontal and vertical use

Espey WD100

- Split housing design

- Multi-part seal rings, radially cut

- Very small operation gap – low leakage

- Dry running

- Self-adjusting seal rings

- Seal rings bear radial shaft movements

- Compensates axial shaft movements

- No sealing components mounted on the shaft and hence no additional shaft vibrations

- Seal rings running contact-free – sliding faces and machine consume no additional power

Espey WD200

- Split housing design

- Multi-part seal rings, radially cut

- Very small operation gap - low leakage

- Dry running

- Self-adjusting seal rings

- Seal rings bear radial shaft movements

- Compensates axial shaft movements

- No sealing components mounted on the shaft and hence no additional shaft vibrations

- Seal rings running contact-free - sliding faces and machine consume no additional power