Situation

The natural gas grid in Great Britain uses centrifugal compressors to ensure consistent gas flow through peaks and troughs in demand.

CobaSeal - the next level of separation seal

The natural gas grid in Great Britain uses centrifugal compressors to ensure consistent gas flow through peaks and troughs in demand.

Contamination of dry gas seals due to bearing oil leakage, resulting in compressor downtimes and loss of Nitrogen pressure.

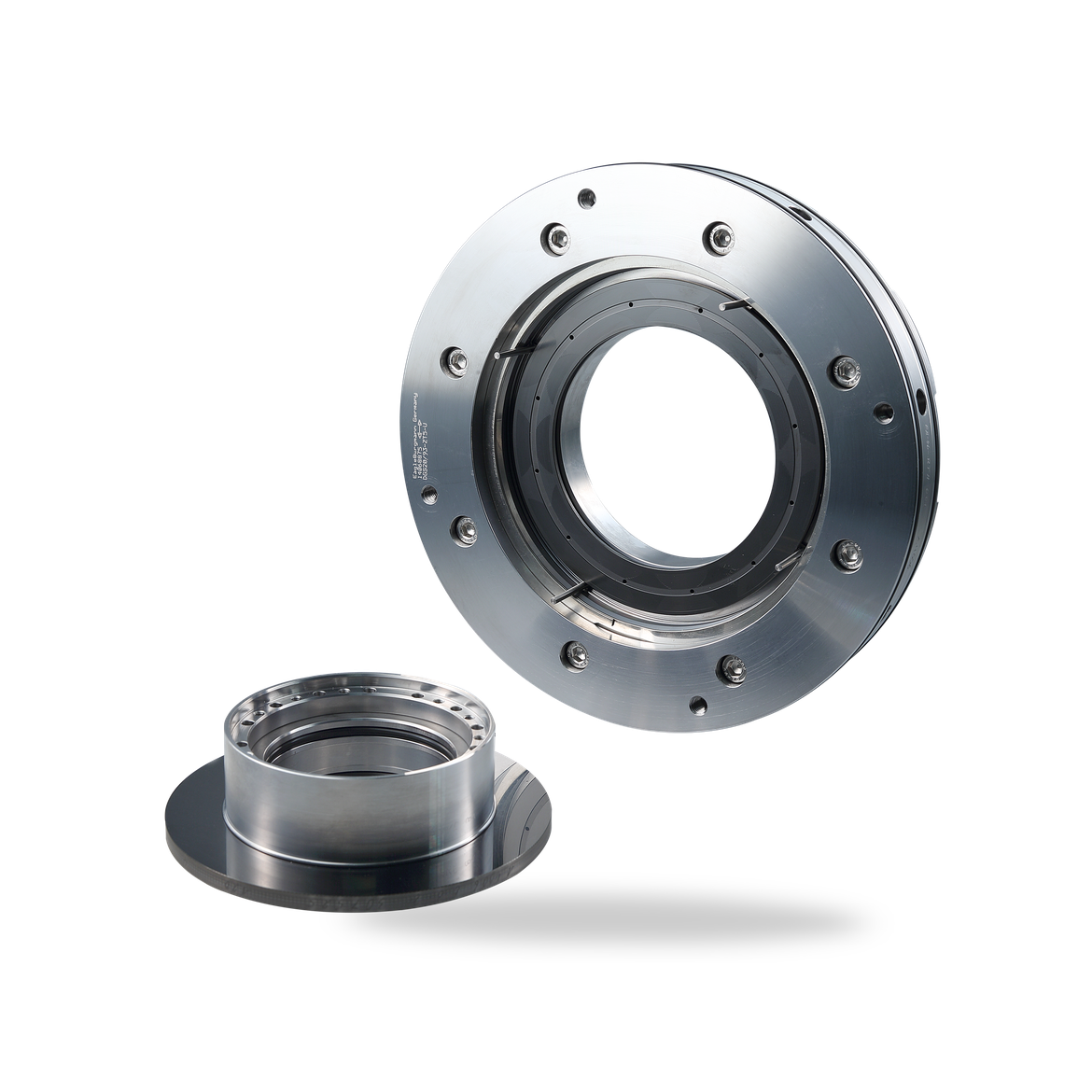

EagleBurgmann dry gas seal with the coaxial separation seal CobaSeal.

Many countries rely on their natural gas grid almost as much as they do their electrical grid, which makes it socially as well as economically imperative for network operators to strive for the utmost in system reliability.

Centrifugal compressors are the beating heart of gas grids, assuring a consistent flow to industrial, commercial and residential customers (including gas-fired power stations) through peaks and troughs in demand.

Compressor performance and availability, in turn, is closely related to the effectiveness of sophisticated compressor shaft sealing technology. The shaft seal creates an impermeable barrier between the pressurized gas supply and unpressurized ambient environment, preventing pressure loss and contamination of the former and protecting the integrity of the compressor. If the

seal performance degrades, the compressor is compromised.

Conventional sealing solutions have served gas producers and distributors well enough, but the quest for a further leap in reliability has led to development of the CobaSeal that can deliver improved compressor availability in LNG liquefaction, transport and gas transmission or any oil and gas compressor application.

This sealing technology is the development EagleBurgmann, a global leader in industrial seal technology, first installed in a collaboration with gas network operator National Grid UK and compressor manufacturer Siemens Energy.

More than 4 years of field operations have confirmed the results of pre-launch testing: the CobaSeal is more robust than older seal types, consistently reliable in all operating conditions, and provides cost savings in the form of reduced Nitrogen gas consumption.

National Grid operates Great Britain’s gas transmission system comprising 7,600 kilometers of high pressure pipeline, including 24 compressor stations. Its Nether Kellet booster station 100 km North of Manchester Manchester utilizes dual gas-turbine driven Siemens STC-CP type centrifugal compressors with the overhung impeller design widely used in gas transmission. The shaft sealing technology used there – a dry gas seal in tandem arrangement with a nitrogen-buffered carbon ring separation seal – has been the industry standard until now. The dry gas seal performs the principal sealing function, while the carbon ring seal protects the dry gas seal against bearing oil contamination and guards against compressor gas contamination of the bearing brackets.

“At Nether Kellet, bearing oil leakage over the existing separation seal was contaminating the dry gas seal, causing an undesirable level of unplanned compressor down time as well as a loss of Nitrogen pressure during pressurized standstill

periods,” says Ferdinand Werdecker, head of compressor seals engineering at EagleBurgmann. “The loss of pressure resulting from the distortion of the carbon ring segments of the seals is linked to low pressure cycling in the pipeline. Low

pressure cycling is part of normal pipeline operations and is unavoidable.”

National Grid and Siemens Energy asked EagleBurgmann in 2010 to help develop a better solution. The customers envisioned a separation seal design that would tolerate vibrations from high gas film stiffness and assure contact free operations in all operating modes. It would be sufficiently robust to eliminate the issue of broken sealing rings. There would be no oil leakage during standstill or low roll operations, gas leakage prevention would be assured, and the new design would boast very low Nitrogen purge gas consumption and fluctuation – reducing operating costs.

Nitrogen (minimum -50 °C (-238 °F)) is used to ensure the carbon rings have sufficient sliding capability for the aerostatic separation seal to achieve lift-off from the compressor shaft after stoppages.

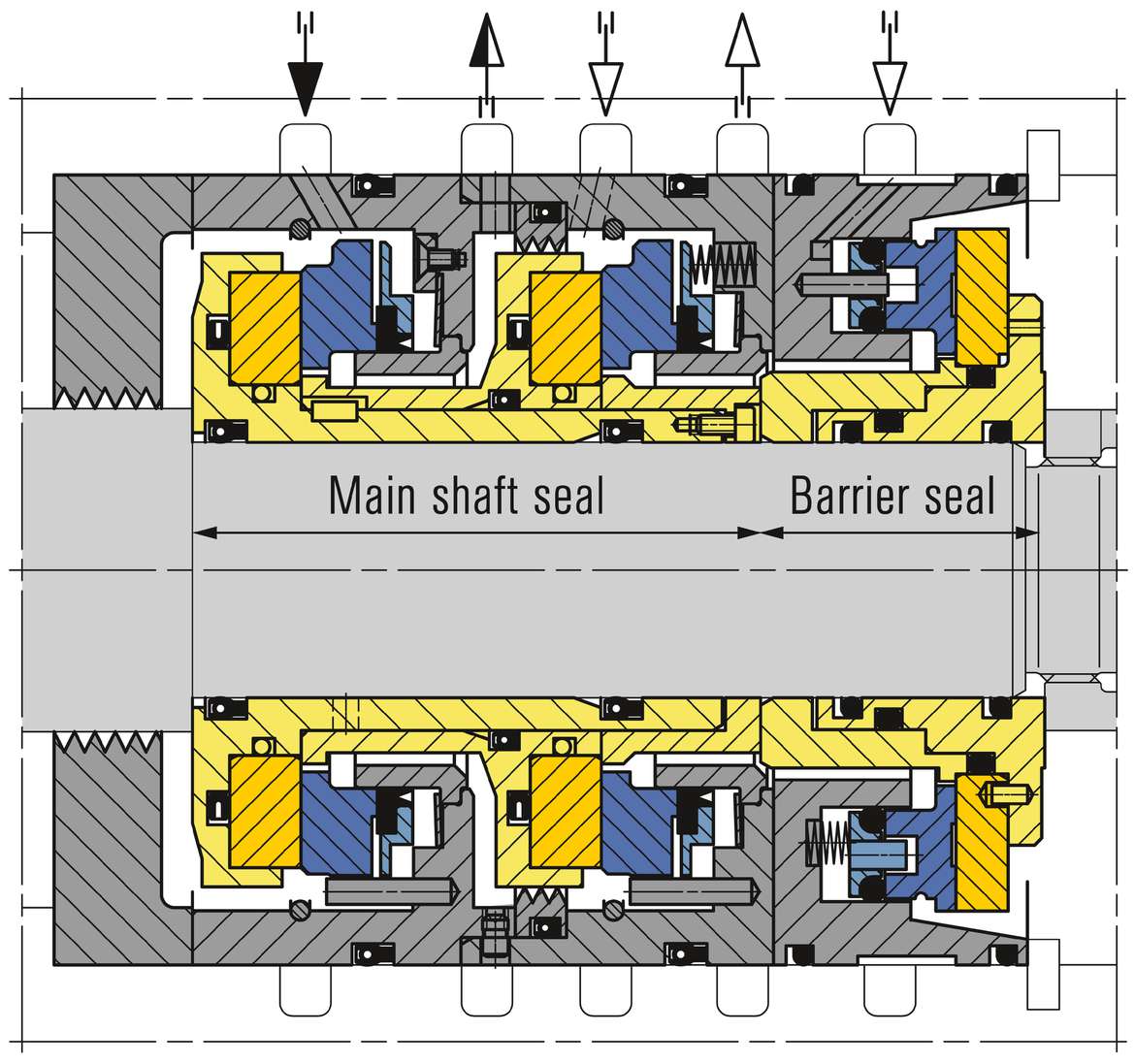

EagleBurgmann’s solution was an industry first: a conventional dry gas seal in tandem with a newly designed coaxial separation type seal substituting for the existing carbon ring seal. The CobaSeal design, similar to that of a dry gas seal, is comprised of a rotating ring made of stainless steel and a spring loaded stationary face made of silicon carbide, both covered with a EagleBurgmann high performance iDLC coating.

The Nitrogen separation gas is routed into the seal by using axial bores through the stationary face into the middle of the rotating seat. The purge gas then separates into two leakage flows – one to the inner diameter towards the secondary vent, the other to the outer diameter of the seal face towards the bearing chamber.

Illustr. 1: Compressor shaft prior to installation

Illustr. 2: Cross section drawing of a typical Dry Gas Seal + Separation seal (EagleBurgmann PDGS + CobaSeal)

Yellow parts = rotating, blue = stationary, gray = housing

Aerostatic as well as aerodynamic lift-off provide separation of the rotating and stationary seal faces as soon as the CobaSeal is pressurized and leads to a wear-free operation. The gas film stiffness eliminates the risk of contact between the rotating ring and stationary seal face during irregular operations such as axial vibrations or micro movements of the compressor shaft.

The CobaSeal has no restrictions with regard to “slow roll”, “turning gear” and “coast down” operations of the compressor that are integral to the demand-driven requirements of a major gas delivery network. The design allows operating pressure of up to 10 barg (145 PSI) in the vent line combined with differential pressure control, which is an additional safeguard against a total failure of the tandem seal arrangement. Also, the risk of process gas leakage towards the bearing brackets is eliminated.

The design underwent extensive shop testing, including the simulation of upset conditions as well as operations at maximum design specification. The seal was tested first for EagleBurgmann’s specifications and then subjected to a witness and acceptance test created especially for field conditions at National Grid.

“All tests were passed with flying colors, including the simulation of a total failure of the dry gas seal in combination with the pressure-controlled supply of the coaxial seal barrier,” says Werdecker. “After all testing, the seat and faces of the tested coaxial seal were in like-new condition. There were no contact marks, demonstrating that the maintenance of separation, essential for extended safe, continuous operations, worked as intended.”

That’s continued to be the case at Nether Kellet since the September 2011 installation of a CobaSeal in a compressor with a 102 mm shaft diameter. “The unit has been subjected to a wide range of operational conditions including surge trials, and normal starts and stops, both running and starting trips, and has clocked in excess of 1,300 operating hours,” says Huub de Bruijn, head compressor service product management at Siemens Energy. “From an operational standpoint, the coaxial separation seal has done exactly what National Grid hoped to achieve: most notably achieving improved compressor availability with extended maintenance intervals. Since installation, unplanned compressor downtime has basically been zero.”

That’s echoed by National Grid’s own assessment. “In general, the operation of the CobaSeal is already proving to be a success. There has been a lot of start-stop operating including emergency shutdown trips and it has endured the harshest of tests; performance testing of the compressor during which time the actual surge line was plotted. There has not been one issue with its operation since installation” says Mike Marcinko National Grid’s responsible asset engineer. Nitrogen consumption is less than half of the rate for a carbon ring seal, in line with results from pre-delivery testing. And there has been no evidence of lube oil in the secondary vent line of the compressor. All of this suggests National Grid can expect wear-free seal operation with maintenance intervals extended up to 10 years.

The EagleBurgmann CobaSeal design can be adapted to all standard seal cavities. The design has been officially certified by Siemens Energy for use with its compressors. In the meantime, other well-known compressor manufacturers certified and ordered the CobaSeal for applications throughout the oil and gas industry worldwide (contact us for more information).

Illustr.: Compressor in operation at Nether Kellet Booster Station

EagleBurgmann CobaSeal -

Performance under severe conditions. Watch the video now!

EagleBurgmann CobaSeal -

Performance under severe conditions. Watch the video now!

Find out more about CobaSeal

Separation seal breakthrough improves UK gas grid compressor reliability. Download the solution flyer!

Between June 2017 and March 2019 the Hengli Group constructed an integrated refining and chemical complex in the Chinese harbor town Dalian where 20 million tons of crude oil are processed every year. EagleBurgmann advised the company Hengli concerning the selection of mechanical seals and supply systems for the whole plant and supplied more than 95 % of the components in use.

In Great Britain, a shortage in natural gas supply has severe consequences: Since the country switched from coal-fired to gas-fired power stations, a gas supply shortage makes households and industrial consumers not only vulnerable to failing heating and gas stoves, but also to power outages. Companies along the value and transportation chain of natural gas are therefore especially dependent on reliable equipment.

Things get hot in rotary kilns, very hot in fact. In the production of cement, for example, the thermometer measures more than 1,000 degrees Celsius. Sealing systems from EagleBurgmann, a company of the Freudenberg Group and EKK, make sustainable contributions to environmental protection, energy efficiency and process reliability under these "fiery" high-temperature conditions.

Our modern civilization is quite literally built upon cement. Today, building materials made from cement are used in buildings, roads, bridges, dams etc. Cement production is a heat-intensive process and causes thermal expansion in duct systems. To compensate this, Indian cement producer Ramco Cement needed fabric expansion joints with a diameter of several meters for two of their plants. On the basis of a close collaboration, EagleBurgmann was able to design components that increase the efficiency of the plant in the long run.

Frequent starts and stops are a severe test for gas-lubricated compressor seals. Installed in an Argentinean combined cycle power plant is an EagleBurgmann supply system that provides a continuous gas flow rate for the seals and adapts it to changing conditions. Since then, the operational reliability of the compressors has increased significantly.

Seals are a risk factor in the production of liquid crystals. If there is even the slightest contamination of the liquid crystals, this will later affect the image quality of the display. Read on to see which sealing solution Merck KGaA uses in paddle dryers for the production of liquid crystals.